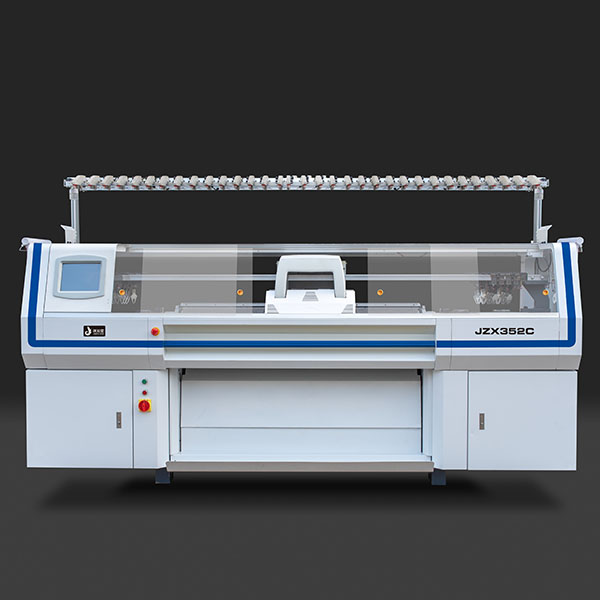

OEM Best Sweater Machine Instructions Factories – JZXC- Nonwasted Comb Flat Knitting Machine – Jinzhixing

OEM Best Sweater Machine Instructions Factories – JZXC- Nonwasted Comb Flat Knitting Machine – Jinzhixing Detail:

Products Description

The model integrates various high and new technologies such as high-speed small carriage, dynamic density control function, fast return technology, The New Carriage and The High-Performance Servo Technology Achieve Fast Inversion and Increase the Production Of 10%-20%.two-way stitch decreasing and continuous knitting innovative technology. Providing stable drawing tension, make the fabric drawing more smoothly, and reliable. And equipped with auto oiling system, compatible with current most programming system. with excellent cost performance, it has achieved economic, practical, efficient, stable effect and it is the best-selling model.

Technical Parameters

| Model | JZX252C JZX352C JZX366C etc |

| Gauge: | 3G 3.5G 5G 5/7G 7G 9G 10G 12G 14G |

| Knitting width: | 52inch、66inch、72inch 、80inch,etc |

| System: | Double system, three system |

| Knitting speed: | Maximum speed 1.4m/s. |

| Cam system: | Adopts‘the motor driven cam direction -changing system’improve knitting speed and stability. And use 5.2inch cam plate and 6inch cam plate as per functional config. “Three position” knitting technology can simultaneously present “knitting”, “tuck”, “partial floating ” and other stitching methods, needle transfer back and forth can be realized at the same time, not restricted by the carriage direction |

| Yarn Feeding system: | 4 pcs yarn rail,16pcs single hole and double hole yarn feeder. |

| Comb taking-down system: | Adopts latest own developed non-waste comb, effectively solve the knitting problem caused by insufficient drawing force, while saving setup yarn usage |

| Soft ware: | Chinese latest controlling system |

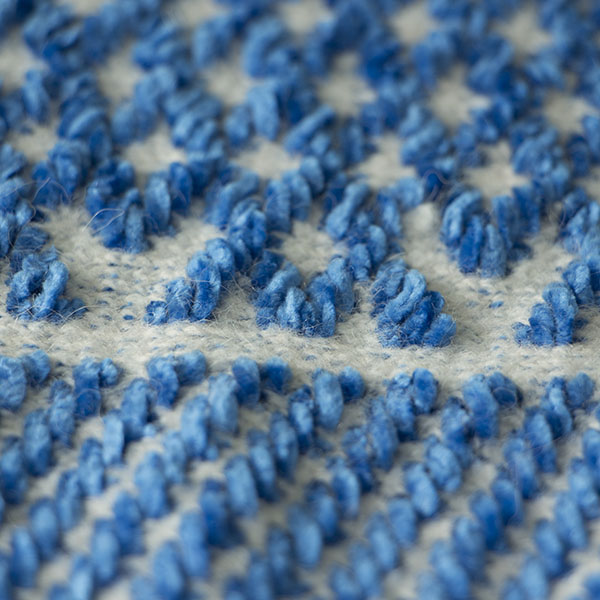

| Knitting function: | plain jersey, rib, reverse structure, full needle etc. basic structure, and tuck, jacquard, pointel, cable, racking stitch, yarn plating, terry, intarsia, partial knitting, and other fancy structure. |

| Density control: | Controlled by Stepper motor, 32 segments selection, adjustable range (0-720) by subdivision technology, with dynamic density function. |

| Operating system: | Using 10.4-inch LED display, graphical interface, USB transmission mode, the system can store a large number of files, according to the production needs at any time to call out, support multi-language switching, simple and efficient |

| Power: | AC220V/380V 50Hz/60Hz, Power Consumption: 1.2KW (two system) 1.5KW (three system) |

| Volume and weight: | JZX252Clength 2950mm, width 980mm, height 1980mm/ net weight 1200kg |

Technical Features

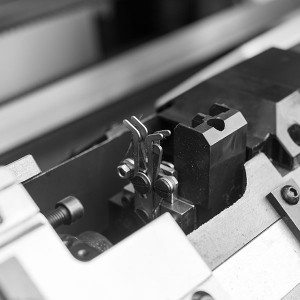

Reliable scissors and clip device for automatic yarn catch and cut operations through system control

Providing stable drawing tension, make the fabric drawing more smoothly, and reliable. Automatically knitting from bottom of fabric without using set-up yarn to avoid unnecessary waste can be realized

Application Case

Product detail pictures:

Related Product Guide:

To create far more benefit for customers is our company philosophy; customer growing is our working chase for OEM Best Sweater Machine Instructions Factories – JZXC- Nonwasted Comb Flat Knitting Machine – Jinzhixing , The product will supply to all over the world, such as: Swaziland, Barcelona, Kyrgyzstan, Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!

Write your message here and send it to us