President Gu said that the recent new development and progress, cooperative innovation and rapid progress made by the enterprise encouraged the company to continue to redouble its efforts. He hoped that entrepreneurs of textile machinery would exchange experience, conduct in-depth discussion, jointly seek new opportunities for mutual cooperation and sustainable development of textile machinery industry, and make greater contributions to industrial technological innovation.

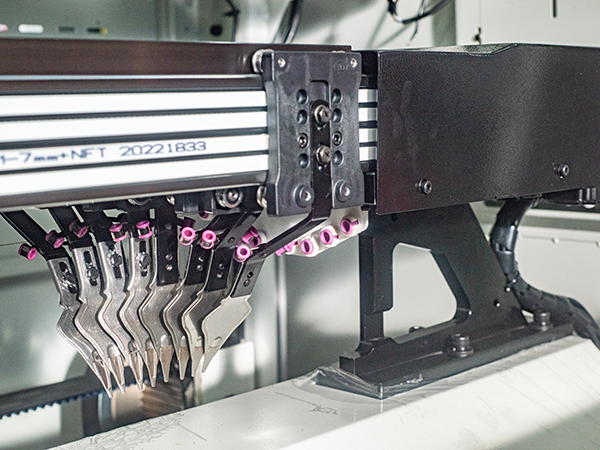

Intelligent self-running feeder greatly changes the traditional mode of the yarn feeder driven by the machine carriage. Each yarn feeder is controlled by an independent servo motor to optimize the yarn feeding process, which can improve the efficiency of about 85% in specific pattern knitting; There are several linear feeding guide rails. The two sides of each guide rail are equipped with smart running yarn feeding components, which can independently control 16 yarn feeders at most. The smart running feeding components include yarn feeders, yarn feeding seat, yarn feeder support strip, U-shaped bearing, bearing mandrel, eccentric wheel, synchronous belt, synchronous belt mounting seat, synchronous belt clamping block, etc. the intelligent running feeder components can flexibly run back and forth on the steel wire track of the guide rail, The yarn feeder can more accurately stay at the parking point, and accurately cooperate with the needle output and take-up of the machine head. It can realize partial jacquard, multi-color inlay, reverse yarn addition ,intarsia and complex patterns that cannot be knitted by ordinary computerized flat knitting machine. When knitting complex patterns, it has higher efficiency, more accuracy and better fabric quality. Because the yarn feeder parking point is accurate, the knitting time is greatly improved, and the generation of broken edges is effectively reduced, so as to reduce the waste rate, save costs and improve benefits for customers.

regarding the phenomenon of yarn floating and yarn spitting in the knitting process of computerized flat knitting machine, a new slide type presser foot device of computerized flat knitting machine is designed. Based on the introduction of the working principle and functional analysis of the conventional presser foot device, the design idea, working method and action analysis of the main mechanism of the slide presser foot device are described in detail, such as eccentric wheel, presser foot, slide, curve, sensor, etc. The application of the presser foot technology of the new computerized flat knitting machine can improve the product quality and equipment knitting speed, and is suitable for the knitting of some special patterns with high process requirements, which provides favorable conditions for the research and development of new wool products.

The use of presser foot technology can realize the non waste yarn setup of sweater knitting, including flat edge non waste yarn raising, curved edge non waste yarn raising, single-sided fabric non waste yarn setup and three-dimensional trim non waste yarn raising. It is pointed out that the non waste yarn bottom knitting technology of computerized flat knitting machine can reduce the production cost of sweater, improve efficiency, save energy and reduce emission.

In the next 10 years, China's garment industry will change from labor intensive to capital and technology intensive. Phase of labor-intensive industry: fully enjoy the demographic dividend. Instead of focusing on RESEARCH and development, it adopts mature traditional technologies, emphasizes sales channels and close short-distance market relations. In the capital-intensive phase: huge wealth accumulation effect. Emphasis is placed on the support of technology, patents, and the legal system, as well as the composition of remote market networks. Financial arrangements at this stage require a large amount of capital in and out, and a rich financial ecology that spreads risks.

The coming of the third industrial revolution and the digital revolution is a hotbed of labor-intensive transformation to capital and technology intensive. Due to the development of information technology, the connotation and extension of the concept of manufacturing industry have changed a lot. At the heart of the third Industrial Revolution is the maker's revolution. Create products using the Internet and the latest digital manufacturing technologies. It is not because of rising costs in developing countries such as China that developed countries are refocusing on manufacturing and moving back.Facing the competition from developing countries, China needs to find a new competitive advantage. The textile industry has the first mover advantage in the first revolution, while the knitting industry has the late mover advantage in the textile industry. The third industrial revolution will certainly bring great advantages to our knitting industry

Post time: Feb-12-2022