TSE The Economic Serial Flat Knitting Machine

Products Description

This model has two styles, the first is a single head single system simple flat machine, the second is a single head double system style, the two styles according to customer needs and configuration. The needle plate can be selected as one processing type or insert type.

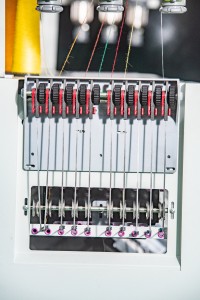

Using Precision needle and 8-segment needle selection system, and the needle plate is quenched by high frequency to meet the production requirements of high-quality collar and all kinds of fabric, due to the selection principle, the carriage movement is faster

And the returning speed is faster than double system, it is more suitable for making most of basic common knitting structure and production productivity is higher

In addition, this facility could be customized as requirement

1. Optional no waste yarn starting base plate; 2. New self-running yarn nozzle technology can be added; 3. According to the configuration character of this model,new technically innovation foot presser equipment could be added as to customers requirement.

Adapt LED touch screen for displaying various knitting related parameters. With a directly needle selection system, small carriage, makes the machine more effectively, motor controlled directly needle selection cam system with simple structure, compact size and

Precision needle and 8-segment needle selection system, and the needle plate is quenched by high frequency to meet the production requirements of high-quality collar fabrics. light weight. The use of the increased thickening fabric winding roller design fully meets the higher requirements of the double-sided organization on the drawing force and enhances the smooth performance of the drawing.

This model can meet the basic production requirements, so it is the preferred model for the customer to start business

Technical Features

more cost-effective, single and double system optional, especially could be equipped with foot presser and insert plate needle bed

Nonwasted yarn comb system Can be equipped with as requirement

Taking use of double detection probe top tension alarm system, doubly ensure the alarming system and provide sufficient and even tension.

Technical Parameters

| Model | TSE152 TSE252 |

| Machine gauge | 7G-14G |

| Width | 52inch 60inch 72inch 80inch |

| Cam system | Direct selection system, support knit、transfer |

| Yarn feeder | 3pc feeder rail,6pcs yarn feeder (standard) |

| Knitting system | Single system /double system |

| Racking function | Controlled by servo motor, maximum L+R movement up to 2inch |

| Drawing device | Stepper motor controlled, high-position roller, special sinker and comb device(optional) |

| Needle bed | One plate needle bed and insert plate needle bed(option) |

| Power | Ac 220v/380v frequency:50/60hz power consumption:1-2kw |

Application Case