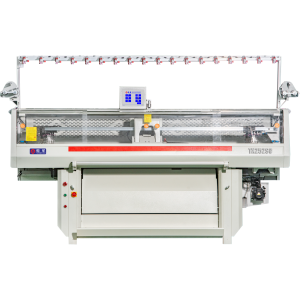

TAF – The Intelligent Feeders Serial Knitting Machine

Products Description

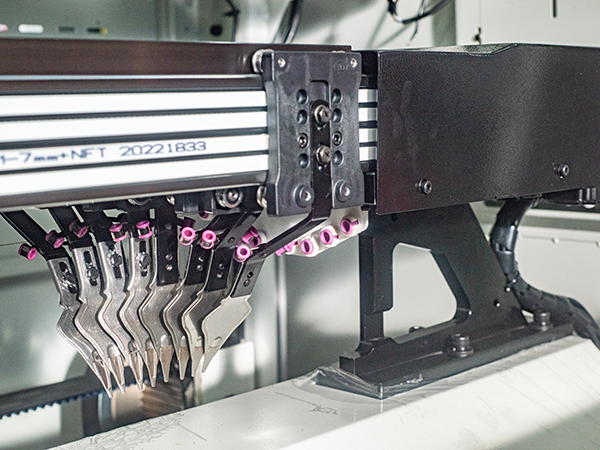

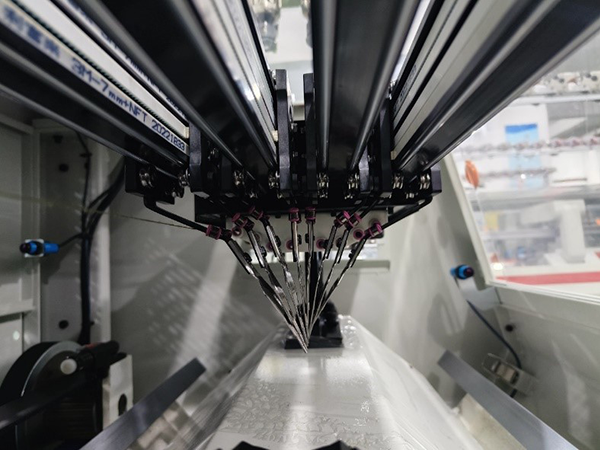

Equipped with 4 pcs arc-shaped feeder rail,16pcs auto motor-driven feeders, the movement of which is controlled by computer up or down. This could precisely realize the knitting of intarsia, inverse plating and reduce running course, to improve knitting efficiency. It is the latest innovative proprietary technology, 16colors Intarsia Structure Can Be Made Maximumly. The Cam System Utilizes Motor-Controlled Needle Raising Structure, Carriage Effective Movement Distance Is Shortened, Carriage Return Become Faster and More Stable.

Technical Parameters

| Model | TAF252 TAF352 |

| Machine gauge | 3G 3.5G 5G 5/7G 7G 9G 10G 12G 14G 16G |

| Knitting width | 52inch、66inch、72inch 、80inch,etc |

| Knitting speed | Maximum 1.4m/s |

| Display | 10.4inch touch screen, support multiple language |

| Feeder alternation | 4pcs feeder rail,8+8 auto running feeder, intarsia and reverse plating structure advantage, knitting efficiency were highly improved |

| Racking function | Controlled by servo motor, maximum L+R movement up to 2inch |

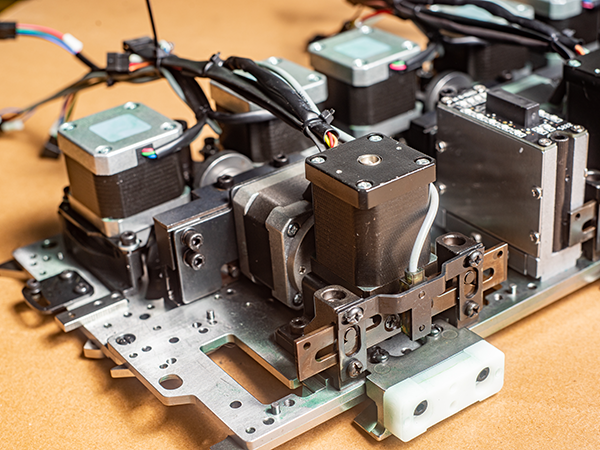

| Drawing device | Stepper motor controlled, high-position roller, special sinker and comb device(optional) |

| Alarm device | Yarn breakage, big knot, racking failure, programming error |

| Main interface | graphical interfaces, easy operation, compatible with usb and network, auto update |

| Power | Ac 220v/380v frequency:50/60hz power consumption:1.5-2kw |

Technical Features

feeder movement is not with carriage, controlled by servo motor independently

feeder positioning is more accurate and more stable

carriage movement course was greatly reduced, especially the efficiency of inlay and intarsia structure increased by 200%, it creates more space for designing patterns

Application Case

Write your message here and send it to us