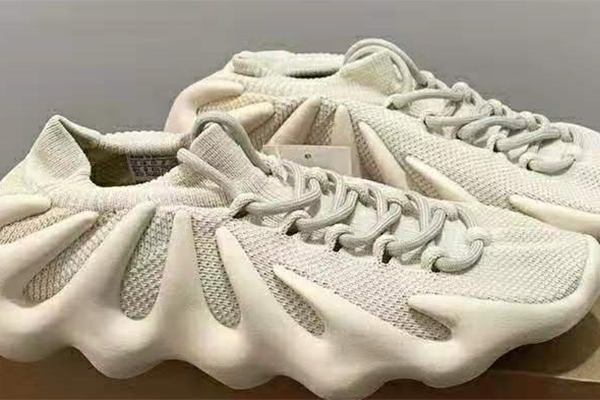

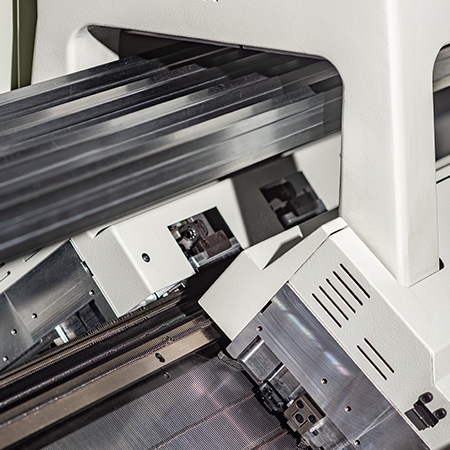

TS-3D Shoes Upper Knitting Machine

Products Description

It owns rapid carriage return ,dynamic density control ,and tight tuck function equipped with high position roller taking down system and latest crossing sinker pressing system which make the pattern of shoes upper structure more abundant and strong 3D effects,Adjustable tight tuck device can fully meet the special needs of the loose or tight tuck structure of the shoe upper, independent pushing needle cam control mechanism, shorten the carriage return time, High-performance servo control technology, the machine's running position is more accurate, and the return is faster. programming system is more intelligent and modularized. operation and production are easier. Suitable for chemical fiber and nature fiber and other mixed material to knit.

Technical Parameters

| Model | TS336 TS252 TS380 |

| Gauge | 12G/14G/16G |

| Width | 36 inch、52 inch、72inch 80 inch |

| Carriage system | Single carriage-double system/three system/four system |

| Running speed | Maximum speed 1.4 m/s |

| Racking | Driven by servo motor,maximum L&R racking distance up to 2 inch |

| Needle selection system | 8 levels of selecting needle, Preliminary needle selection system |

| Sinker | Front and rear crossing type sinker system,support fast needle increasement |

| Auto-stop system | Yarn breakage, yarn knot, rewind, impact, piece finish, overload, Specific line stop, program error etc. |

| Safety equipment | Anti-noise and dust system, infrared detector system emergency stop |

| Taking down roller | High position roller,segment adjustment |

| Carriage cam system | Innovative designed smaller carriage driven by full motor systemHigher stability and efficiency,Tight tuck cam make pattern more vivid |

| Power consumption | Voltage: AC220V/380V frequency:50Hz/60Hzcapacity: 1.5KW(double system), 2.0KW(three system), 2.5KW(four system) |

Technical Features

Initiative smaller carriage design,faster movement,light and stable.

Special sinker system and high-position roller setup, fabric drawing more stable and even. shoes upper with 3D effect.

Adjustable tight tuck device could meet the special requirement of particular structure, independent rising cam design make the carriage returning speed faster.

Application Case